PRODUCTS

Introducing 5CE + Primer as standard

We are pleased to announce that all WE-EF luminaires are now supplied with 5CE+ Primer as standard at no extra charge. We have made this decision in order to streamline our offering, improve our product quality and strengthen our brand in the Australian and New Zealand markets.

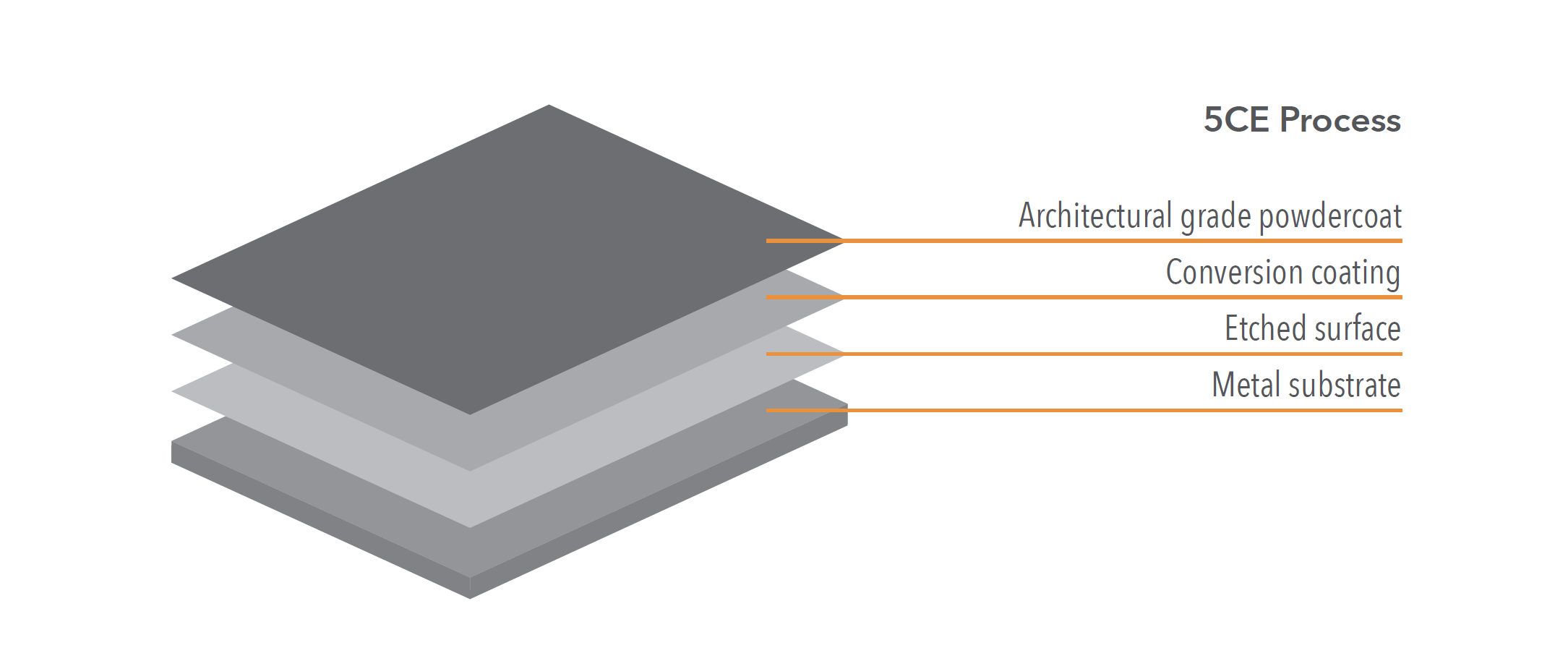

WE-EF 5CE + Primer Corrosion Protection System

A decisive quality feature for exterior luminaires is their resistance to corrosion. Outstanding and long-lasting anti-corrosion properties can only be achieved by a comprehensive, integrated approach. The result of many years of research and development, hands-on testing and experience, WE-EF’s unique 5CE system encompasses five critical elements:

1. Substrate

2. Conversion coating

3. Powder

4. PCS hardware

5. Process control

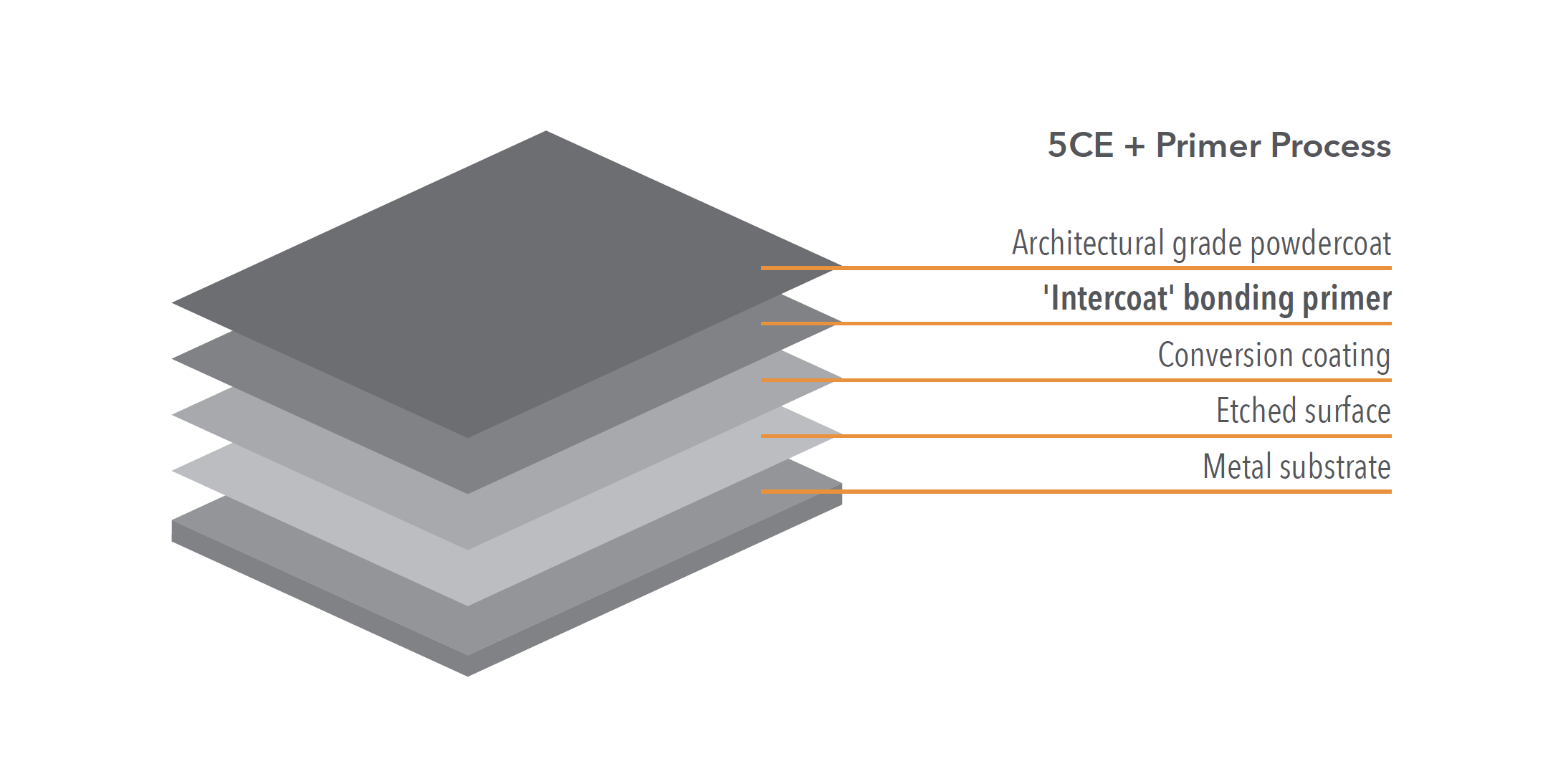

For installations where corrosion protection over and above the 5CE system is required, 5CE + Primer introduces an additional element to the process:

1. Substrate

2. Conversion coating + Primer

3. Powder top coat

4. PCS hardware

5. Process control

What is Primer?

Immediately after conversion coating, a specially formulated ‘intercoat’ bonding, epoxy primer is electrostatically bonded (80-100 μm), and initially semi-cured in a 180°C oven. Following the subsequent application of the polyester powder top coat, full curing and essential ‘intercoat’ bond is achieved at 200°C. Top coat and primer are perfectly merged.

When treated with WE-EF’s 5CE + Primer Superior Corrosion Protection system, the WE-EF luminaires are robust and able to withstand the toughest conditions such as coastal weather.